The relentless thud-thud-THUD of a traditional mechanical press is a sound synonymous with manufacturing for decades. It’s the heartbeat of factories worldwide, punching, forming, stamping, and assembling the products that fill our lives. Yet, beneath that familiar rhythm lies a world of limitations – wasted energy, unforgiving tolerances, inflexible processes, and the constant specter of downtime. What if you could replace that brute force with intelligent power? What if your press could *think*, *adapt*, and move with the grace and precision of a surgeon? Enter the Servo Press System: not just an upgrade, but a fundamental rethinking of how we shape metal and materials. This isn't merely a new machine; it's the cornerstone of the next industrial evolution.

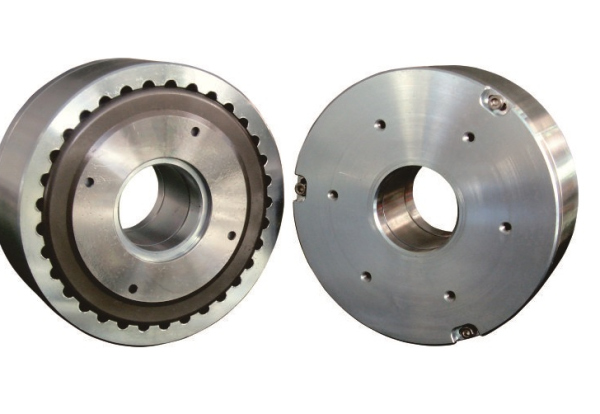

Gone are hysteresis brakes of being shackled to fixed stroke lengths and monotonous cycles. Imagine a press where the ram doesn't just mindlessly hammer down. Picture it instead as a virtuoso performer, capable of infinitely variable strokes, speeds, and dwell times, all orchestrated with breathtaking digital precision. That’s the essence of servo press technology. Powered by high-torque, direct-drive servo motors eliminating complex gearboxes and clutches, it grants unprecedented control over every single millimeter of the ram’s movement. This programmable flexibility is the game-changer. 🎯

Let's delve into why this technological leap is causing such a seismic shift across industries from precision automotive components and intricate electronics to robust appliance manufacturing and cutting-edge aerospace parts:

1. **Precision That Borders on Perfection: The End of \"Close Enough\" 🎯**

* **Micron-Level Control:** Forget tolerances measured in fractions of an inch. Servo presses operate in the realm of microns (thousandths of a millimeter). This exquisite control over position, speed, and force at every point in the stroke is simply unattainable with mechanical or hydraulic counterparts. Think of forming delicate electronic connectors, achieving perfect coining finishes, or ensuring flawless fitment in critical safety components. It eliminates springback inconsistencies and delivers part-to-part uniformity that elevates quality to new heights.

* **Adaptive Force \u0026 Speed Profiles:** Need a gentle touch at the start of forming, a surge of power mid-stroke, and a precise, controlled deceleration right before bottom dead center? With a servo press, you program it. This ability to tailor the force and speed curve precisely to the material's behavior and the part's geometry minimizes stress concentrations, reduces cracking or tearing in challenging materials (like advanced high-strength steels or lightweight alloys), and dramatically improves material yield. No more forcing the material to conform to the machine's limitations; the machine adapts flawlessly to the material's needs.

2. **Unlocking Impossible Geometries \u0026 Processes: Innovation Unleashed 💡**

* **Multi-Stage Forming in a Single Hit:** Why use three separate presses or complex progressive dies when one servo press can perform multiple distinct forming actions within a single stroke? Program the ram to pause, reverse slightly, change speed, and apply different forces at different positions. This enables complex shapes – deep draws, intricate embossing, combined punching and forming – to be achieved more efficiently and with far simpler, less expensive tooling.

* **The Power of the Dwell:** Controlled dwelling – holding the ram at a specific position under precise pressure – is a superpower. It allows materials to relax and flow, enabling deeper draws without rupture, achieving sharper bends with less springback, and facilitating processes like precision calibration or in-die heat-assisted forming. Try *that* effectively with a flywheel spinning at a fixed speed!

* **Silent Near-Net Shaping:** The precise control allows forming much closer to the final net shape, significantly reducing or even eliminating secondary machining operations. This translates directly to lower costs, faster throughput, and less material waste.

3. **Energy Efficiency: Slashing Costs \u0026 Carbon Footprint, Silently 🌱💰**

* **Demand-Only Power:** This is perhaps the most dramatic operational savings. A traditional mechanical press consumes massive energy just to keep its massive flywheel spinning continuously, regardless of whether it's actively forming a part. Hydraulics constantly bleed energy through valves and heat generation. A servo press? It only consumes significant energy during the actual forming portion of the stroke. During the non-working parts of the cycle (ram return, dwell, setup), energy consumption plummets. Real-world savings often reach 30-60% or more compared to equivalent mechanical presses. In an era of soaring energy costs and intense focus on sustainability, this is transformative.

* **Regenerative Braking:** Many advanced servo systems capture the energy generated during the ram's deceleration and return stroke and feed it back into the power system, further boosting efficiency. It's like hybrid technology for your factory floor.

4. **Speed Meets Flexibility: Agile Manufacturing Realized 🔄⚡**

* **Optimized Cycle Times:** While peak strokes-per-minute might be comparable to mechanical presses in simple operations, servo presses often achieve *faster overall production rates* for complex parts. How? By eliminating wasted motion. Shorter strokes (only what's needed for *this* job), faster acceleration/deceleration profiles tailored to the task, and the ability to perform multiple operations in one hit all contribute to reduced total cycle time per part.

* **Instant Changeovers:** Changing production runs on a traditional press often involves physically adjusting mechanical stops, changing cams, or reconfiguring hydraulic settings – a time-consuming manual process prone to errors. Servo press changeovers are predominantly digital. Load a new program, potentially adjust tooling, and you're running the next job. This drastically reduces downtime and makes small batch sizes and high-mix production economically viable. Agile manufacturing isn't just a buzzword; it's achievable with the right tools.

* **Reduced Noise \u0026 Vibration:** Servo drives are inherently quieter than the clatter of mechanical clutches/brakes or the whine of hydraulic pumps. The smoother motion profiles also generate significantly less vibration. This creates a better, safer, and more productive work environment and reduces stress on both tooling and the press structure itself, extending lifespan.

5. **Intelligence Built-In: The Smart Factory Foundation 📊🤖**

* **Real-Time Monitoring \u0026 Data:** Every stroke generates valuable data – actual force applied, position accuracy, cycle time, energy consumption. Modern servo press controllers collect and analyze this data continuously. This enables predictive maintenance (spotting bearing wear or misalignment before failure), immediate detection of process deviations (e.g., material thickness variation, tool wear, misfeeds), and comprehensive production reporting for traceability and optimization.

* **Closed-Loop Control \u0026 Error Proofing:** Integrated sensors (load cells, position encoders) provide constant feedback. The system can instantly detect if actual force exceeds programmed limits (indicating potential die clash or double blank) or if position is off (indicating tool wear or material issues) and automatically stop the press to prevent catastrophic damage. This protects your valuable tooling investment and prevents production of non-conforming parts.

* **Seamless Integration:** Servo presses readily communicate via industry-standard protocols (OPC UA, MQTT, Ethernet/IP). They plug seamlessly into MES (Manufacturing Execution Systems) and plant-wide IIoT (Industrial Internet of Things) networks, becoming intelligent nodes feeding data and receiving instructions within the smart factory ecosystem.

**Beyond Hype: Tangible Results Across Industries**

The theoretical advantages are compelling, but what does this look like on the actual shop floor? Consider these scenarios:

* **Automotive Tier 1 Supplier:** Struggling with cracking in high-strength steel door reinforcements using a conventional press. Implementing a servo press allowed programming a multi-step forming profile with controlled speed reductions and precise dwells at critical points. Result: Crack elimination, reduced scrap by 95%, and increased tool life by 40%. The energy savings paid for the press differential within two years.

* **Electronics Connector Manufacturer:** Producing ultra-fine pitch connectors required multiple secondary operations after stamping due to springback and tolerance issues. A micro-precision servo press with closed-loop force control and adaptive forming profiles achieved net-shape forming. Result: Elimination of two secondary machining stations, scrap reduction of 60%, and capacity increased by 35% due to faster cycle times and reduced handling.

* **Appliance Maker:** Needing to produce multiple door panel variations on the same press line. Traditional changeovers took 90+ minutes. A servo press with quick-change tooling and digital program recall reduced changeover time to under 15 minutes. Result: Dramatically increased flexibility to meet fluctuating demand, reduced WIP inventory, and the ability to profitably run smaller batches.

**Addressing the Elephant in the Room: Investment \u0026 Perception**

Yes, the initial capital cost of a servo press system is typically higher than a comparable mechanical press. This is often the first hurdle. However, focusing solely on the sticker price is a profound mistake. The Total Cost of Ownership (TCO) picture tells the real story:

1. **Energy Savings:** As highlighted, 30-60% energy reduction is standard. Over a 10-15 year lifespan, this represents hundreds of thousands, often millions, in saved electricity costs.

2. **Material Savings:** Reduced scrap due to superior precision and process control directly boosts your bottom line. Higher yield means less raw material purchased and less waste disposed of.

3. **Tooling Savings:** Longer tool life (due to softer hits, controlled motion, clash protection) and potentially less complex tooling designs significantly reduce die costs and maintenance.

4. **Productivity Gains:** Faster cycle times for complex parts, drastically reduced changeover times, and less downtime due to predictive maintenance and crash protection all increase overall equipment effectiveness (OEE) and throughput.

5. **Quality Premium:** The ability to consistently produce parts with tighter tolerances, better surface finishes, and complex geometries allows you to command higher prices, win more demanding contracts, and reduce costly warranty claims and rework.

6. **Reduced Maintenance:** Simpler mechanical architecture (no clutches, brakes, complex gearboxes, hydraulic pumps/valves/hoses) translates to lower routine maintenance costs and less unscheduled downtime.

7. **Increased Flexibility:** The ability to handle a wider variety of parts with minimal reconfiguration future-proofs your investment and opens new market opportunities.

When viewed through the TCO lens, servo presses frequently demonstrate a compelling ROI, often paying back the initial premium well within their operational life. They are not just a production tool; they are a strategic asset driving competitiveness.

**Choosing the Right Servo Press Partner: It's More Than Specs**

Investing in a servo press is a significant decision. Beyond looking at tonnage, bed size, and stroke length, consider these crucial factors:

* **Control System Intelligence \u0026 Openness:** Is the control system truly powerful and user-friendly? Does it offer sophisticated programming capabilities (force profiles, position windows, multi-step sequences)? Is it open for easy integration with your existing automation and data systems? Avoid proprietary \"black boxes.\"

* **Drive System Quality \u0026 Reliability:** The servo motor and drive are the heart. Look for robust, industrial-grade components from reputable suppliers known for longevity and performance under demanding conditions. Understand the cooling system (liquid vs. air).

* **Frame Rigidity \u0026 Construction:** Precision is only as good as the machine holding it. A stout, vibration-damping frame is non-negotiable for achieving micron-level accuracy consistently, especially at higher tonnages. Look for advanced designs like pre-stressed tie-rods or monoblock frames.

* **Service \u0026 Support:** This is paramount. Does the manufacturer have a proven global support network? Are technicians readily available? What is the parts supply chain like? Look for vendors who offer comprehensive training and proactive support agreements. Your uptime depends on it.

* **Application Expertise:** Does the supplier understand *your* specific applications? Can they provide proven simulation support or reference successful installations in similar industries? Partner with someone who speaks your language and understands your challenges.

**The Future is Programmable: Are You Ready to Lead?**

The servo press revolution is not looming on the horizon; it's here, reshaping production floors globally. It represents a fundamental shift from brute force to intelligent force, from fixed cycles to programmable motion, from energy guzzlers to sustainable solutions, from isolated machines to connected data hubs.

This technology empowers manufacturers to achieve unprecedented levels of quality, efficiency, flexibility, and sustainability. It’s the key to unlocking innovation in part design, conquering challenging materials, responding rapidly to market demands, and thriving in an increasingly competitive landscape.

Continuing to rely solely on traditional presses means accepting limitations: limitations on part complexity, limitations on material utilization, limitations on energy efficiency, limitations on agility, and ultimately, limitations on your growth and profitability.

The question isn't *if* you should explore servo press technology, but *when* and *with whom*. The manufacturers embracing this intelligent forming technology today are the ones building resilience, securing their competitive edge, and defining the future of making things.

Don't just hear the difference (or rather, the quietude). *Feel* the precision. *Experience* the efficiency. *Unlock* the potential. The era of intelligent forming has arrived. Is your shop ready to step into it? 🚀 Let's build the future, one precise stroke at a time.