You hear it before you see it. The rhythmic, jarring THUD-THUD-THUD shaking the concrete floor. A haze of lubricant hangs in the air. An operator, masked and gloved, feeds blanks into a massive mechanical beast, flinching slightly with each deafening cycle. Over in the corner, the maintenance crew huddles around a hydraulic unit, faces grim, tools scattered – another unscheduled downtime event eating into production targets. Sound familiar? This isn't just nostalgia; it's the daily reality for countless shops still wrestling with traditional presses. But a quiet revolution is reshaping precision manufacturing, and its name is the Servo Press Machine. Forget the incremental upgrades of the past; this is a fundamental leap. It’s not merely replacing old iron; it’s redefining what's possible in forming, stamping, and assembly. It’s about control, precision, efficiency, and intelligence converging on the shop floor in a way that fundamentally alters your production economics and product quality. Buckle up; we're diving deep into why ignoring this technology isn't just conservative, it's potentially perilous for your bottom line.

Beyond Brute Force: The Intelligence Engineered In

Traditional presses – whether venerable mechanical flywheel types or powerful hydraulic workhorses – operate on principles of immense force applied in relatively crude strokes. They smash, they push, they punch. Speed is often king, but control? Flexibility? Energy thriftiness? These were secondary considerations, traded off for raw power and perceived reliability. The servo press shatters this paradigm by putting *intelligence* at the heart of the motion.

Think of it like the difference between a sledgehammer and a master sculptor's chisel. Both can shape material, but the precision, finesse, and control offered by the chisel are incomparable. How does the servo press achieve this magic? It boils down to a few core technological pillars:

1. **The Servo Motor \u0026 Drive: The Digital Muscle:** At its core, a high-torque, high-response servo motor replaces the conventional clutch/brake or hydraulic pump system. This motor is directly coupled to the press drive mechanism (often a precision ballscrew or sophisticated linkage system). Why does this matter? Control. Pure, digital control. The servo drive receives constant feedback on the motor's position, speed, and torque. This creates a closed-loop system where the controller can make micro-adjustments thousands of times per second to ensure the ram (the moving part that does the pressing) follows the EXACT programmed path, regardless of load variations or material inconsistencies. Imagine pressing a delicate sensor housing – the servo press can apply precisely the required force at precisely the right speed, holding it for the exact dwell time needed, eliminating cracking or deformation common with uncontrolled deceleration in mechanical presses.

2. **Unshackled Motion Profiles: Programmable Precision:** This is where the true superpower emerges. Forget being stuck with a fixed stroke curve determined by mechanical linkages. A servo press lets you *program* the ram motion profile with incredible detail. Need a slow approach to precisely locate the tooling? Done. Require ultra-high speed during the non-working part of the stroke to maximize parts-per-minute? Easy. Critical need for a specific, controlled velocity during the forming operation itself to manage material flow and springback? Program it. Want a prolonged dwell at bottom dead center for perfect forming or curing? Set the duration. Need multiple pressing steps within a single stroke? Configure it. This flexibility is revolutionary. It means you can optimize the process perfectly for *your specific part and material*, dramatically improving quality, reducing scrap, and enabling the forming of complex geometries previously deemed impossible or too risky on conventional machines.

3. **Silent Efficiency: The Green (\u0026 Quiet) Machine:** Walk past a traditional mechanical press in full swing – it’s loud. Really loud. Hydraulic units whine and hiss. Servo presses? They are remarkably quiet. The elimination of the crashing clutch/brake engagement, the roaring flywheel, and the constant hydraulic pump noise creates a significantly better (and safer) working environment. But the quiet extends beyond acoustics to energy consumption. Mechanical presses consume significant energy just spinning the massive flywheel, even when idle. Hydraulic presses leak energy constantly through heat and system losses. Servo presses only consume significant energy when the motor is actively driving the ram. During dwells, deceleration, and even holding position at bottom dead center, energy draw plummets. Studies consistently show energy savings of 30-70% compared to traditional presses, a massive operational cost reduction that compounds year after year. Sustainability isn't just a buzzword; it's a tangible cost saving delivered daily.

The Tangible Triumphs: Where Servo Presses Deliver Real-World Dominance

This sounds great in theory, but what does it actually translate to on the production floor? Let’s get concrete:

* **Precision That Pays Dividends:** Eliminating the fixed stroke curve and enabling micro-positioning control dramatically improves part consistency. Tight tolerances? Standard. Reduced springback? Achievable through optimized dwell profiles. Minimized part marking or distortion? Possible with controlled approach and release speeds. This precision directly reduces scrap rates, improves assembly fit, and enhances final product performance and reliability. For industries like aerospace, medical devices, or advanced electronics, where micron-level precision is non-negotiable, servo presses are becoming the *only* viable option. Think implantable medical components requiring flawless surface finishes and exact dimensions – servo control makes this repeatable perfection a reality.

* **Flexibility: The Agile Manufacturing Enabler:** Need to change over to a different part? Servo presses excel. Programmable stroke lengths and shut heights mean fewer mechanical adjustments. Digital recipe recall loads the exact motion profile, tonnage limits, and monitoring parameters for the new job in seconds. This slashes setup times, making small batch production and high-mix environments vastly more efficient and economical. No longer is dedicated, inflexible machinery required for every part variant. One servo press can often handle a diverse range of tasks, maximizing asset utilization.

* **Unlocking Complex Geometries \u0026 Materials:** Traditional presses struggle with advanced high-strength steels (AHSS), exotic alloys, or intricate forms requiring multi-stage compression within one hit. The servo press's ability to precisely control force and velocity profiles throughout the stroke allows these challenging materials and shapes to be formed consistently and without damage. Imagine deep drawing ultra-thin aluminum for battery casings without tearing, or forming complex automotive structural components from AHSS with predictable springback. The servo press makes it feasible.

* **Predictive Power \u0026 Process Intelligence:** Modern servo presses are data hubs. They continuously monitor and record critical parameters: actual tonnage curve vs. programmed, ram position accuracy, motor current (indicating load), cycle time, and energy consumption. This data isn't just for display; it's the foundation for predictive maintenance (detecting abnormal loads indicating bearing wear or misalignment) and sophisticated process monitoring. Imagine setting tight tolerance windows on the tonnage profile for each stroke. If a part is missing, the material is too thick, the lubrication fails, or a tool breaks, the press detects the anomaly (tonnage too low or too high) *immediately* and can stop automatically, preventing the production of scrap or catastrophic tool damage. This level of in-process quality control is transformative, moving from reactive inspection to proactive prevention.

* **Extending Tool Life Dramatically:** How tools die matters. The violent impact and shock loading inherent in traditional presses are brutal on tooling. Servo presses eliminate this shock. The controlled acceleration and deceleration, the ability to gently \"kiss\" the material and apply force smoothly, significantly reduces stress on punches, dies, and guides. Less shock means fewer micro-fractures developing, less chipping of cutting edges, and dramatically extended tool life. For high-value precision tooling, this alone can justify the investment in servo technology through reduced tooling costs and less frequent changeovers.

Addressing the Hesitation: Beyond the Initial Price Tag

Let's be honest: the upfront cost of a servo press is typically higher than an equivalent tonnage traditional mechanical press. This is often the first hurdle. But focusing *solely* on the purchase price is a classic, and costly, mistake. The true cost of ownership must be evaluated over the machine's operational lifespan. Consider:

* **Energy Savings:** As highlighted, 30-70% lower energy bills are not trivial. Over 10-15 years of operation, this represents a massive sum, often enough to cover a significant portion of the initial price premium. Calculate your current press energy consumption and project the savings – the numbers are usually startlingly persuasive.

* **Reduced Scrap \u0026 Rework:** Higher precision and better process control directly translate to fewer defective parts. Less material wasted, less labor wasted on rework or sorting, less disruption to flow. In high-value components, saving even a fraction of a percent in scrap can yield huge annual savings.

* **Extended Tooling Life:** Doubling or tripling the life of complex, expensive progressive dies or forming tools is a direct cost avoidance. Fewer tool purchases, less frequent tool maintenance downtime, lower tooling inventory costs.

* **Increased Productivity:** Faster setup times (flexibility), higher effective strokes per minute (optimized motion profiles), and significantly reduced unscheduled downtime (higher reliability, predictive maintenance) all contribute to getting more good parts out the door faster. Maximizing Overall Equipment Effectiveness (OEE) is the holy grail, and servo presses are proven OEE boosters.

* **Lower Maintenance Costs:** Simpler mechanical architecture (no complex clutch/brake systems, no hydraulic fluid leaks or pump failures), combined with less violent operation, leads to fewer breakdowns and lower routine maintenance costs. No more constant clutch lining changes or hydraulic hose replacements.

* **Improved Safety \u0026 Ergonomics:** Quieter operation reduces noise hazards. Smoother motion reduces vibration. Advanced safety systems integrated with the digital control (light curtains, area scanners, muting functions tied to ram position) enhance operator safety. Reduced physical strain from less dramatic machine movements contributes to better ergonomics.

* **Future-Proofing \u0026 Data Integration:** Servo presses are inherently digital machines ready for Industry 4.0. The wealth of process data they generate is invaluable for continuous improvement initiatives, digital twins, and integration into Manufacturing Execution Systems (MES). Investing in servo technology positions your shop for the data-driven manufacturing future.

Choosing Your Servo Press Partner: It's More Than Specs

Not all servo presses are created equal. Beyond tonnage and bed size, key considerations include:

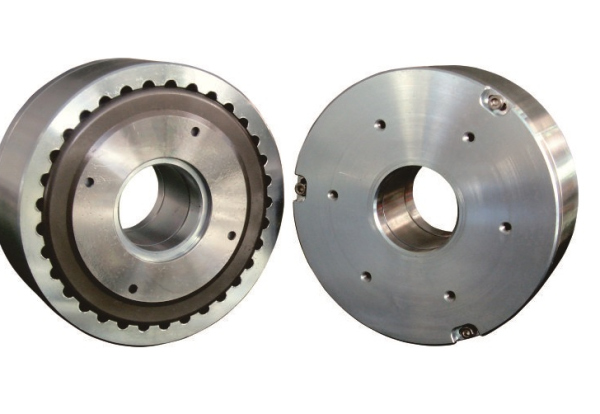

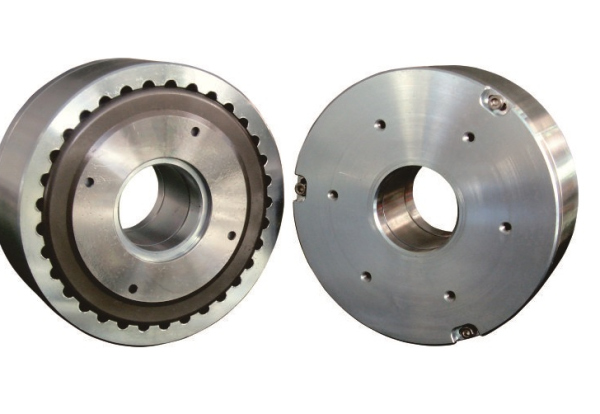

* **Drive Mechanism:** Ballscrew drives offer exceptional precision but may have lower maximum speeds or tonnage limits in very high-force applications. Linkage drives (often hybrid mechanisms) can achieve high tonnage and speeds while still offering significant programmability advantages over traditional presses. Understand the trade-offs for your specific application.

* **Control System Power \u0026 Openness:** The brains matter. A powerful, user-friendly CNC-style controller is essential for leveraging the full programmability. Look for hysteresis brakes (OPC UA, MTConnect) to ensure seamless integration with your factory network.

* **Frame Rigidity \u0026 Construction:** Precision demands stability. A robust, well-designed frame with high rigidity is non-negotiable to handle off-center loads and maintain accuracy under high tonnage.

* **Application-Specific Features:** Do you need high-speed blank feeding integration? Precise coining capability? Deep drawing expertise? Tandem press line controls? Ensure the machine builder has proven experience and features tailored to your primary applications.

* **Service \u0026 Support:** This technology is sophisticated. Having a partner with deep technical expertise, readily available local service engineers, comprehensive training programs, and a robust spare parts supply chain is critical for maximizing uptime and your return on investment. Don't underestimate the value of a true partnership.

The Future is Programmable: Are You Ready?

The servo press machine is more than just another piece of factory equipment. It signifies a shift towards intelligent, adaptable, and supremely efficient manufacturing. It moves production away from brute force and compromise towards finesse, control, and data-driven optimization. The benefits – breathtaking precision, unprecedented flexibility, dramatic energy savings, extended tool life, predictive capabilities, and seamless integration – are not just promises; they are demonstrable realities transforming shops worldwide.

The question isn't really *if* servo technology will become the dominant force in precision pressing; that trajectory is clear. The question is, how soon will you harness its power? The early adopters are already reaping the rewards: lower costs per part, higher quality, faster time-to-market for complex products, and a significant competitive edge. The sound of the future isn't a deafening thud; it's the quiet hum of a servo motor delivering unparalleled precision, cycle after perfect cycle. Don't let your competitors hear it first.

It’s time to reimagine what your press shop can achieve. The silent revolution is here. Embrace it. 🏭✨