The air hums. Not with the nervous energy of a crowded room, but with the focused, potent thrum of raw power being harnessed, measured, and understood. Deep within research labs, manufacturing floors, and cutting-edge development facilities worldwide, a quiet revolution is unfolding. At its heart lies an unsung hero, a master of precision and insight: the dynamometer. This isn't just another piece of industrial equipment gathering dust; it's the indispensable oracle whispering truths about power, torque, and efficiency that propel innovation forward. If you're serious about engineering excellence, optimizing performance, or simply ensuring your product delivers on its promise, understanding and embracing the dynamometer is no longer optional – it's mission critical.

Imagine you've poured years of research, countless resources, and boundless passion into developing a revolutionary new electric motor. The design is elegant, the simulations promising. Prototypes whirr to life, seemingly perfect. But how do you *know*? How do you quantify its true torque curve under peak load? How do you measure its efficiency across its entire operating range, not just at a single, ideal point? How do you guarantee it won't falter after hours of grueling operation? Guesses, simulations, and gut feelings aren't enough. Enter the dynamometer. It doesn't just measure; it interrogates. It subjects your creation to real-world stresses, meticulously recording its every grunt, groan, and triumph of performance. It transforms abstract potential into concrete, actionable data. Without it, you're navigating the complex landscape of mechanical or electrical power blindfolded.

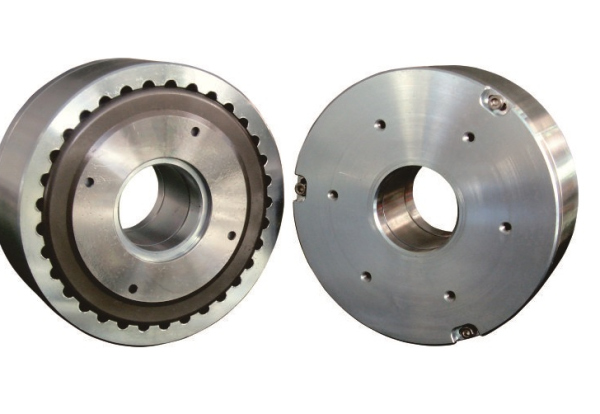

So, what exactly *is* this technological sentinel? At its core, a dynamometer (or \"dyno\" for those in the trenches) is a sophisticated device designed to measure force, torque, and power – typically rotational power output, though linear variants exist. Think of it as a highly calibrated brake system coupled with incredibly precise sensors. The device under test (DUT) – be it an engine, an electric motor, a gearbox, a turbine, or even a bicycle crankset – is coupled to the dynamometer. As the DUT spins, the dyno applies a controlled load, absorbing the power generated. Simultaneously, an intricate network of sensors captures data points thousands of times per second: rotational speed (RPM), torque applied (Newton-meters or Pound-feet), and from these, power (Watts, Kilowatts, or Horsepower) is precisely calculated. Temperature, vibration, electrical characteristics – modern dynos capture it all, painting a comprehensive picture of performance.

The magic lies in the different ways dynamometers apply and manage this load. Each type offers unique advantages:

1. **The Hydraulic Dynamometer (The Fluid Powerhouse) 💧🌀:** Picture powerful water swirling within a casing. As the DUT spins rotors inside a water-filled chamber, the resistance created by the fluid absorbs the power. Adjusting the water flow controls the load. Pros? Massive power absorption capabilities, relatively simple construction, excellent for high-inertia loads like large diesel engines. Cons? Can be less precise at very low speeds, requires significant water flow and cooling infrastructure, and the load isn't as instantly controllable as some other types. Think heavy-duty truck engines, marine propulsion systems, and large industrial power plants.

2. **The Eddy Current Dynamometer (The Electromagnetic Brake) ⚡🧲:** Here, electromagnetism takes center stage. The DUT spins a rotor disc within a magnetic field generated by stationary coils. As the disc cuts through these magnetic lines of force, it generates swirling electrical currents (\"eddy currents\") within the disc itself. These currents create their *own* magnetic field, opposing the original field, resulting in a braking force. The beauty? Varying the strength of the electromagnetic field via electric current provides incredibly fast and precise control over the load. Pros? Excellent controllability, wide speed range, relatively compact for their power capacity, minimal inertia effects. Cons? Power absorbed is dissipated as heat, requiring robust cooling systems, and they can't act as a motor (typically). These are the workhorses of automotive engine development, electric motor testing, and transmission validation.

3. **The AC or DC Regenerative Dynamometer (The Power Recycler) 🔁⚡🔋:** This is where things get really clever – and sustainable. These sophisticated dynamometers don't just absorb power as heat; they convert the mechanical power from the DUT back into usable electrical energy. An AC or DC motor/generator acts as the dynamometer. When loading the DUT, it functions as a generator, converting mechanical energy into electricity. This electricity can then be fed back into the building's power grid or used to power other equipment within the test cell. Pros? Dramatically reduced operating costs (less wasted energy as heat), precise motor-like control, capable of motoring (driving the DUT for startup or simulating downhill conditions), excellent low-speed torque capability. Cons? Higher initial investment, more complex control systems. These are increasingly popular in automotive R\u0026D (especially for hybrids and EVs), aerospace, and anywhere energy efficiency and advanced testing capabilities are paramount.

4. **The Powder Dynamometer (The Friction Maestro) ✨⏳:** A less common but interesting type uses fine magnetic powder. The DUT spins an inner rotor inside an outer shell filled with this powder. Applying an electromagnetic field causes the powder particles to lock together, creating friction and absorbing power. Controlling the field strength controls the load. Pros? Smooth, vibration-free operation, good torque capacity. Cons? Heat dissipation can be a challenge, precision might not match eddy current or regenerative types. Often used in specialized applications like testing clutches or brakes.

Choosing the right dyno isn't a one-size-fits-all decision. It's a strategic choice dictated by your specific needs: the power range you need to test, the required speed range, the level of precision demanded, whether you need motoring capability, your budget, and the available infrastructure (like power and cooling). Consulting with experienced dynamometer suppliers is crucial to navigate this landscape effectively. Don't just buy a dyno; invest in the right *testing solution*.

**Beyond Horsepower: The Myriad Applications Shaping Our World 🌍🚗✈️🔧**

The dynamometer's reach extends far beyond simply printing out peak horsepower numbers on a chart. Its fingerprints are on virtually every machine that moves us, powers us, or builds our world. Let's explore its critical roles:

* **Automotive R\u0026D \u0026 Validation (The Proving Grounds) 🚗🏁🔥:** This is perhaps the most visible domain. From the throaty roar of a performance V8 to the near-silent whine of an EV motor, dynos are the crucible where engines and powertrains are forged and refined. They simulate extreme conditions: blistering desert heat, freezing arctic cold, punishing mountain climbs, endless highway cruising – all within the controlled, repeatable environment of the test cell. Engineers map performance curves, optimize fuel injection or battery management strategies, validate durability under relentless stress cycles (think hundreds of hours at full load), diagnose elusive problems, and ensure emissions compliance long before a prototype ever hits the road. For electric vehicles, dynos are indispensable for characterizing motor efficiency, thermal management, regenerative braking performance, and overall powertrain integration. Without dyno validation, that sleek new car would be a gamble, not a guarantee.

* **Electric Motor \u0026 Generator Excellence (The Spark of Efficiency) ⚡🔌🌱:** As the world electrifies, the demand for high-efficiency, reliable motors and generators explodes. Dynamometers are the gatekeepers of quality. Manufacturers use them to rigorously test every design iteration, measuring torque ripple, efficiency maps across thousands of operating points (crucial for applications like EVs where range is king), thermal performance under load, vibration characteristics, and noise levels. Whether it's a tiny servo motor in a surgical robot, a powerful traction motor for an electric bus, or a massive generator for a wind turbine, the dyno provides the data to ensure it performs flawlessly, efficiently, and quietly.

* **Industrial Power \u0026 Reliability (Keeping the Wheels Turning) 🏭⚙️🛠️:** Power plants rely on dynos to test critical components like gas turbines, diesel generators, and large pumps before they are installed. Maintenance teams use portable dynos to verify the performance of repaired motors and generators onsite, ensuring they meet spec before going back into service, preventing costly downtime. Conveyor systems, crushers, mixers – any industrial machine with a rotating heart benefits from dyno testing to validate design, troubleshoot issues, or confirm performance after overhaul.

* **Aerospace \u0026 Marine Propulsion (Mastering Extreme Environments) ✈️🚢🌊:** Pushing the boundaries of flight and navigation demands absolute reliability. Aircraft engines (jet turbines, turboprops) undergo exhaustive dyno testing to verify thrust, fuel consumption, and performance at simulated high altitudes and extreme temperatures. Marine engines face salt, waves, and constant load – dyno testing ensures propulsion systems and auxiliary generators can handle the harsh marine environment reliably for years. The stakes are incredibly high; dyno testing is non-negotiable for safety and performance certification.

* **Research \u0026 Academia (Pushing the Envelope) 🎓🔬💡:** Universities and research institutions leverage dynamometers as fundamental tools for discovery. They enable groundbreaking research into new combustion concepts, advanced electric motor topologies using exotic materials like high-temperature superconductors, renewable energy systems (like optimizing wind turbine drivetrains or hydroelectric generators), and fundamental studies of friction, lubrication, and materials science under dynamic loading. The dyno provides the empirical evidence that validates theoretical models and drives innovation.

* **Performance Tuning \u0026 Enthusiast Realm (Squeezing Every Drop) 🏍️🔧💨:** Walk into a reputable performance shop, and you'll likely find a chassis dynamometer. While hysteresis brakes from the engine dynos used in R\u0026D – these measure power *at the wheels*, accounting for drivetrain losses – the principle is similar. Tuners use them to meticulously calibrate engine management systems, optimize turbocharger boost profiles, and validate performance gains from modifications. Enthusiasts get the hard numbers to back up their passion. It’s about precision tuning for maximum, reliable performance, whether on the track or the street.

**Deciphering the Oracle: Understanding Dyno Data \u0026 Testing Nuances 📊🔍🧠**

Seeing a dyno graph for the first time can feel like deciphering an ancient script. Let's break down the key elements:

* **The Torque Curve:** This line shows the twisting force produced by the DUT (in N·m or lb-ft) plotted against engine or motor speed (RPM). A strong, flat torque curve across a wide RPM range is often desirable for responsiveness and drivability. Peak torque tells you the maximum force available.

* **The Power Curve:** Derived from torque and RPM (Power = Torque x RPM / Constant), this line shows the actual work being done (in kW, HP, or PS). Peak power gets the headlines, but the shape of the curve – how power builds and where it peaks – is crucial for understanding real-world performance characteristics.

* **Efficiency Maps (Especially for Electric Motors):** These are often color-coded contour plots showing efficiency (%) across a matrix of torque and RPM points. This reveals the \"sweet spots\" where the motor operates most efficiently – vital for maximizing range in EVs or minimizing energy costs in industrial applications. Identifying zones of poor efficiency helps target design improvements.

* **Auxiliary Data:** Modern dyno tests capture a treasure trove of additional data: coolant temperature, oil temperature/pressure, intake air temperature, exhaust gas temperatures (for combustion engines), fuel flow/energy consumption, electrical voltages/currents (for motors), vibration spectra, and more. Correlating these parameters with the torque/power curves provides deep insights into system health, limitations, and optimization opportunities.

Testing methodology is paramount. Rigorous, standardized procedures ensure results are repeatable, comparable, and meaningful. Key factors include:

* **Stabilization:** Allowing temperatures (coolant, oil, dyno water, etc.) to stabilize at the target operating point before recording data.

* **Calibration:** Regular, traceable calibration of the dynamometer's torque and speed sensors is non-negotiable for accuracy. Trustworthy dyno facilities adhere to strict calibration schedules.

* **Environmental Control:** For ultimate precision, especially in R\u0026D, test cells control ambient temperature and humidity to simulate specific conditions accurately. Even barometric pressure corrections are applied.

* **Test Cycles:** Applying defined load and speed profiles over time (like standardized driving cycles for emissions testing or simulated duty cycles for industrial machinery) to assess real-world performance and durability.

* **Data Acquisition \u0026 Analysis:** High-speed data logging captures every nuance. Powerful software then analyzes vast datasets, generates insightful reports and visualizations, and helps engineers spot trends and anomalies.

**Investing in Insight: The Tangible ROI of Dynamometer Testing 💰📉🔼**

Yes, a high-performance dynamometer system represents a significant capital investment. But viewing it purely as a cost is a profound mistake. It's an investment with a demonstrably powerful return:

* **Faster Time-to-Market:** Identify and resolve design flaws early in the virtual and prototype stages within the test cell, drastically reducing costly design iterations and late-stage rework. Get your superior product to market faster than competitors relying on guesswork or limited testing.

* **Superior Product Quality \u0026 Reliability:** Rigorous dyno testing uncovers weaknesses – thermal issues, vibration problems, efficiency bottlenecks, unexpected load sensitivities – that might only surface catastrophically in the field. Fixing these proactively leads to robust, reliable products that build brand reputation and loyalty. Fewer warranty claims, higher customer satisfaction.

* **Optimized Performance \u0026 Efficiency:** Pinpoint inefficiencies. Tune combustion engines for maximum power *and* best fuel economy. Characterize electric motors to minimize energy losses, extending battery life in EVs or reducing operating costs in factories. Extract every ounce of useful performance. In a world focused on sustainability and cost savings, efficiency is king.

* **Enhanced Durability \u0026 Extended Lifespan:** Subjecting components to accelerated life testing on a dyno – simulating years of wear and tear in weeks or months – validates designs and materials under controlled, measurable stress. This results in longer-lasting products, reduced maintenance costs for end-users, and enhanced brand value.

* **Data-Driven Decision Making:** Replace hunches and assumptions with hard data. Dyno testing provides the objective evidence needed to make informed decisions about design changes, material selections, manufacturing processes, and performance claims. Justify R\u0026D spend with quantifiable results.

* **Competitive Advantage:** In fiercely competitive markets, the ability to innovate faster, guarantee superior quality, and deliver demonstrably better performance and efficiency is a game-changer. Dyno testing provides the empirical proof to back up your marketing claims and win contracts.

**Choosing Your Partner in Precision: What to Look For 🤝🔧✅**

Selecting a dynamometer solution isn't just about buying hardware. It's about choosing a technology partner. Here's what matters:

* **Expertise \u0026 Experience:** Look for suppliers with deep domain knowledge in *your* specific application (automotive, EV, industrial, aerospace, etc.). They should understand your unique challenges and goals. Ask for references and case studies.

* **Technology \u0026 Performance:** Evaluate the core technology (eddy current, regenerative, etc.). Does it meet your power, speed, and accuracy requirements? What are the capabilities of the control system? How sophisticated is the data acquisition and analysis software?

* **Customization \u0026 Integration:** Rarely is one dyno setup perfectly off-the-shelf for complex needs. Can the supplier provide tailored solutions – custom mounting interfaces, specific cooling configurations, integration with existing test cell instrumentation or control systems?

* **Calibration \u0026 Support:** Inquire about calibration procedures, traceability (to national standards like NIST), and frequency. Robust technical support, readily available spare parts, and comprehensive training for your engineers are essential for minimizing downtime and maximizing your investment's value over its lifespan.

* **Future-Proofing:** Consider scalability. Will the system accommodate potential future increases in your testing requirements? Is the supplier committed to ongoing software updates and technology advancements?

**The Future Beckons: Where Dynamometer Technology is Headed 🔮🚀🔬**

The world of dynamometry is far from static. It's evolving rapidly to meet the demands of increasingly complex and integrated systems:

* **Hybrid \u0026 Electric Powertrain Focus:** Testing complex systems combining internal combustion engines, electric motors, power electronics, batteries, and sophisticated control systems requires new approaches. \"Powertrain\" or \"eAxle\" dynamometers test these integrated units holistically. Battery emulation capabilities integrated into regenerative dynos allow testing of electric motors and drives without needing the actual battery pack present.

* **\"Hardware-in-the-Loop\" (HIL) Integration:** Dynos are increasingly becoming part of larger HIL simulation environments. The physical DUT runs on the dyno, while the rest of the vehicle (suspension, brakes, even virtual road conditions and traffic) is simulated in real-time software. This allows incredibly realistic testing of interactions and control systems long before a full vehicle prototype exists.

* **Enhanced Connectivity \u0026 Data Analytics:** The Industrial Internet of Things (IIoT) is hitting the test cell. Modern dynos offer seamless connectivity, feeding vast amounts of data into cloud platforms. Advanced analytics, machine learning, and AI algorithms can then mine this data to predict failures, optimize test procedures automatically, identify subtle correlations invisible to the human eye, and provide deeper, faster insights.

* **Increased Automation \u0026 Robotics:** Automating processes like coupling/decoupling the DUT, changing dyno configurations, and conducting predefined test sequences reduces operator time, minimizes human error, increases throughput, and allows for unattended testing (like overnight durability runs).

* **Push for Higher Energy Efficiency:** Regenerative dynamometers will become even more dominant as energy costs rise and sustainability pressures mount. Expect advancements in regenerating power with minimal losses and smarter ways to utilize the recovered energy within facilities.

* **Miniaturization \u0026 Specialization:** As technology shrinks (think drones, medical devices, robotics), the demand grows for smaller, more specialized dynamometers capable of testing micro-motors and tiny actuators with extreme precision.

**The Indispensable Truth: Power Measured is Power Mastered 💪📏🏆**

In the relentless pursuit of progress, where innovation cycles accelerate, efficiency is paramount, and reliability is expected, the dynamometer stands not as a mere instrument, but as a fundamental enabler. It is the rigorous auditor of claims, the revealer of hidden truths, the stress-testing crucible, and the optimization engine. It transforms the abstract concept of mechanical or electrical power into streams of pure, actionable intelligence.

Whether you are crafting the next generation of zero-emission vehicles, designing motors that power life-saving medical equipment, optimizing the heart of a wind turbine sweeping majestically across the plains, or simply fine-tuning a performance engine to perfection on a Saturday afternoon, the dynamometer is your indispensable ally. It provides the certainty in a world of variables, the data amidst the noise, the roadmap to peak performance and unwavering reliability.

To innovate without measuring is to build on sand. To optimize without data is to navigate without a compass. Embrace the silent sentinel. Invest in the oracle of power. Unleash the true potential of your creations by mastering the measure of their might. The dynamometer isn't just a test machine; it's the bedrock of engineering confidence and the catalyst for the next great leap forward. Don't just guess. Know. Measure. Master. 🔧📈🚀